WS

Extractor

Application

The WS type vacuum workstation extractor is used:

- for extracting dust, gases and solid particles from machines for processing metal, wood and plastics, sandblasting devices, concrete grinders, etc.

- as an industrial vacuum cleaner, device for collecting granules.

Construction

1. Side-channel fan equipped with a special pair of steel silencers. The exhaust silencer is additionally equipped with a non-return valve protecting the device against the flow of air in the opposite direction (accidental phase change in the electric motor) and against contamination from the outlet side of the fan. SC type side-channel fans are used in WS vacuum workstation exhausters.

2. A set of bag filters (dimensions Ø100x600mm). The filter cloth is covered with a layer of Teflon and ensures the separation of particles above 5 microns. The bags are stretched over a structure made of galvanized steel mesh. The hood has the function of self-cleaning the filters by means of the reverse air flow direction through the filters.

3. Container for coarse waste and for impurities falling from the filter cloth after using the self-cleaning function of the filters. The container is easily detached from the overall structure by releasing three hooks.

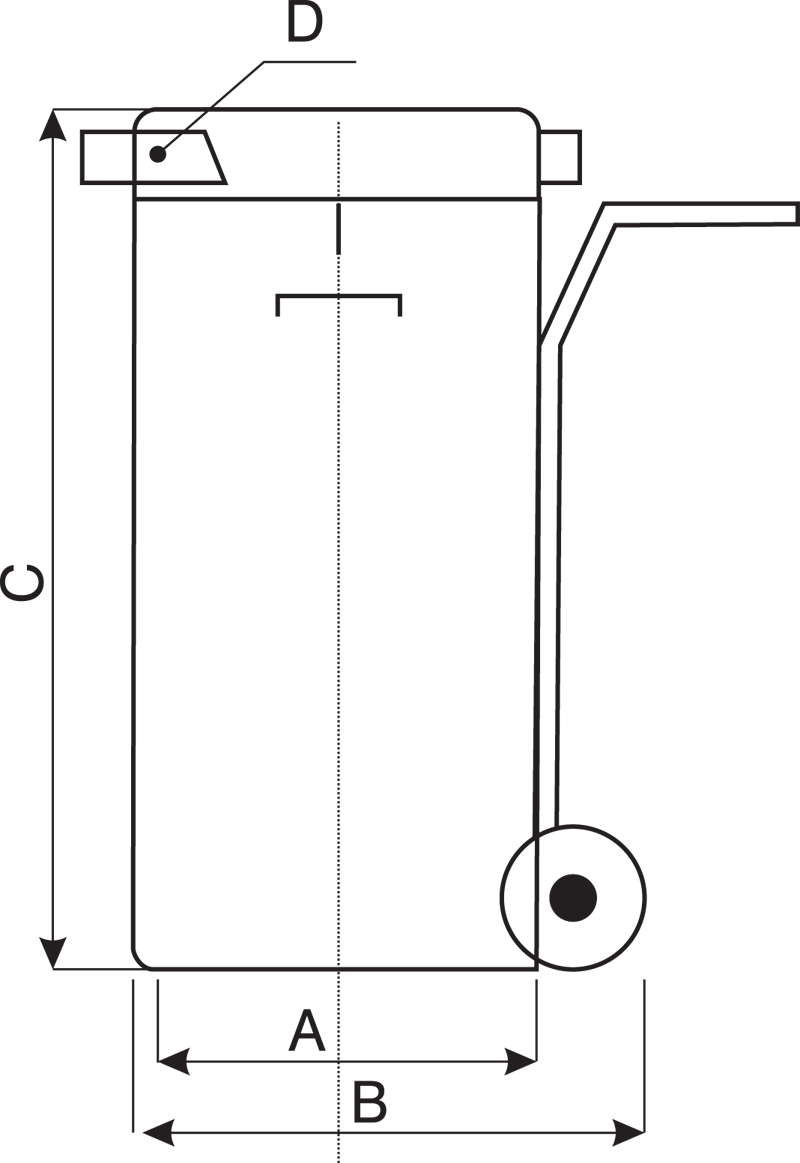

4. A transport trolley equipped with a handle for carrying devices by means of a crane or an overhead crane and wheels with a diameter of 200mm.

5. Control board with a start switch, thermal protection and a 16A socket equipped with a standard phase inverter (which allows the motor rotation to be switched in the case of an incorrectly wired power socket). The WS40 version is additionally equipped with a Y / Δ switch.