Fan Selection Software

Operating point

Select fan type

TCBB/TCBT

Axial-flow duct fan

Range of cylindrical cased axial flow fans fitted with aluminium impellers and manufactured from high grade rolled galvanised steel and protected against corrosion by cataforesis primer and black polyester paint finish.

Construction

Range of cylindrical cased axial flow fans fitted with aluminium impellers and manufactured from high grade rolled galvanised steel and protected against corrosion by cataforesis primer and black polyester paint finish.

All models are supplied with pre-wired wiring junction box located on the outside of the fan casing for easy wiring access. Available, depending upon the model, with single or three phase motors in 2, 4 or 6 poles.

Motor

- Single phase motor (TCBB) or three phase motor (TCBT).

- Models 250, 315, 355 and 400: External rotor motor, IP44, Class F, thermal protection, working temperature from -40ºC to +40ºC.

- Models 450, 500, 560, 630 and 6/710: IP65, Class F, thermal protection, working temperature from -40ºC to +70ºC.

- Models 4/710 and 800: IP55, Class F, working temperature from -40ºC to +40ºC.

- All motors are speed controllable by autotransformer except models /4-560H, /4-630, 710 and T/800.

- Three phase motors are speed controllable by inverter.

Electrical supplies:

- Single phase 230V-50Hz, (Capacitor located inside the wiring terminal box).

- Three phase 230/400V-50Hz or 400V-50Hz.

Additional information

Standard air direction: form (B) configuration (impeller over motor).

On request

- Air direction: form (A) configuration (motor over impeller).

- From Ø450 to Ø800, three phase motors 2 speed, 4/8 poles.

Technical assistance

Catalog card

- User manual 2,62 MB

- Declaration of conformity (CE) 364,88 KB

- Declaration of conformity (CE) 364,97 KB

- Declaration of conformity (CE) 366,71 KB

- Declaration of conformity (CE) 370,79 KB

- Declaration of conformity (CE) 366,71 KB

- Declaration of conformity (CE) 364,97 KB

- Declaration of conformity (CE) 370,79 KB

- Declaration of conformity (CE) 364,88 KB

- CAD drawings 1,33 MB

- Electrical connection diagram 44,87 KB

- Electrical connection diagram 22,06 KB

- Electrical connection diagram 22,96 KB

Work characteristics

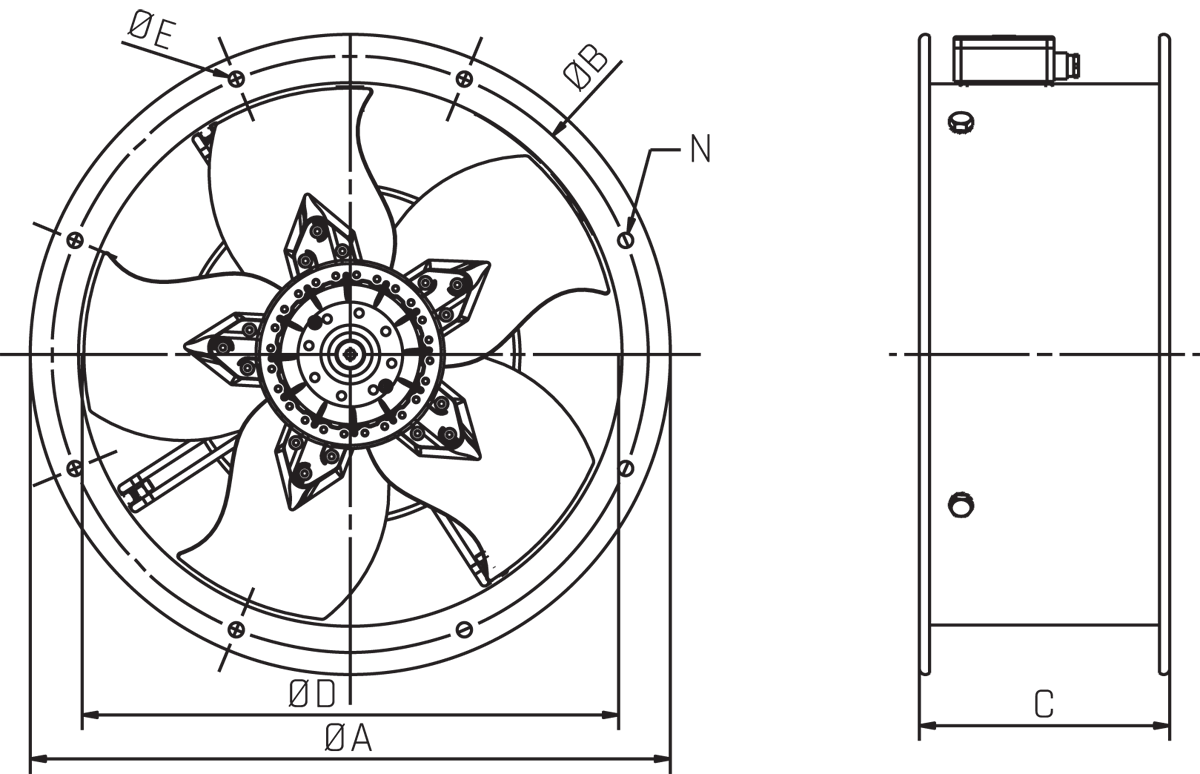

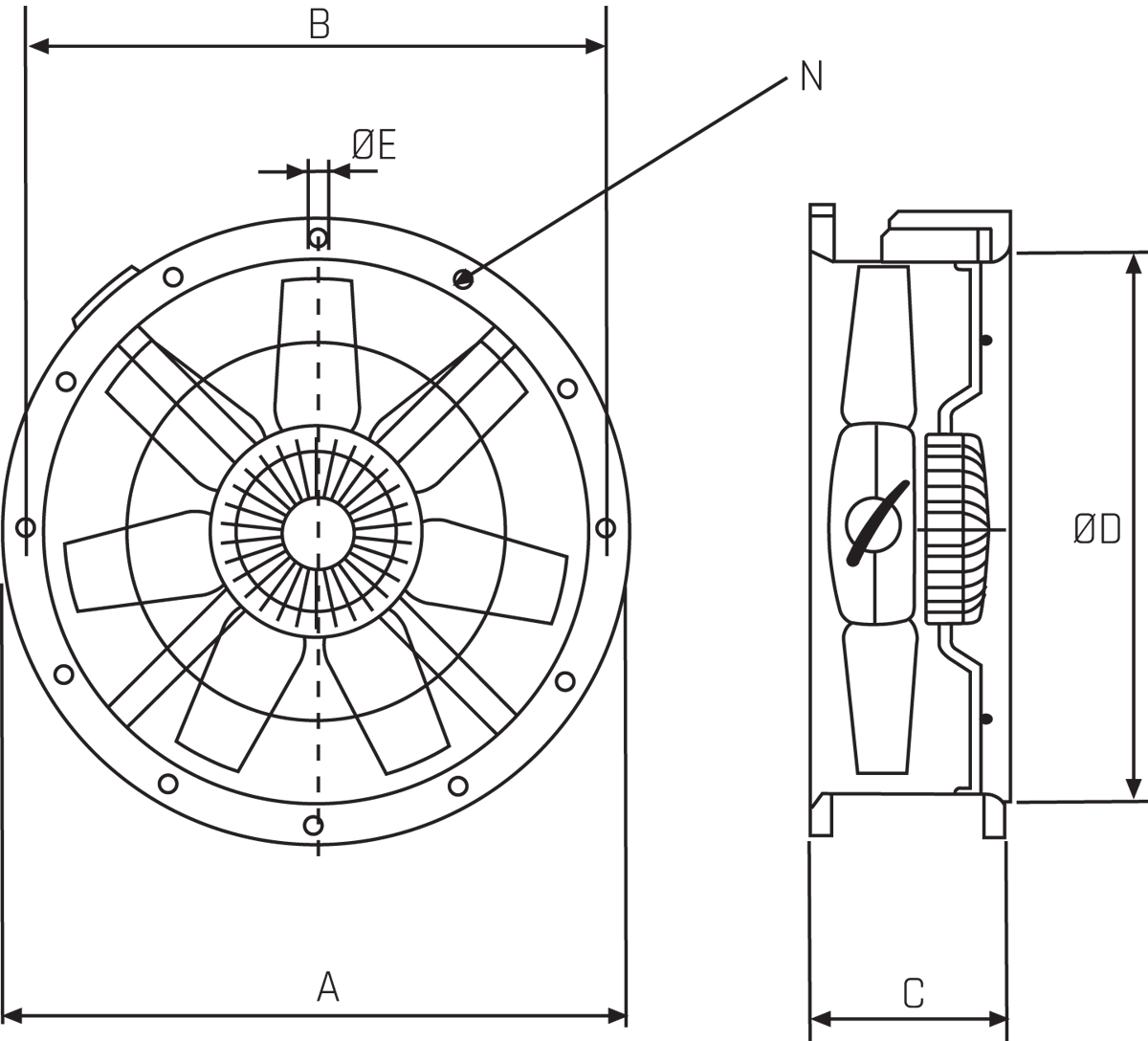

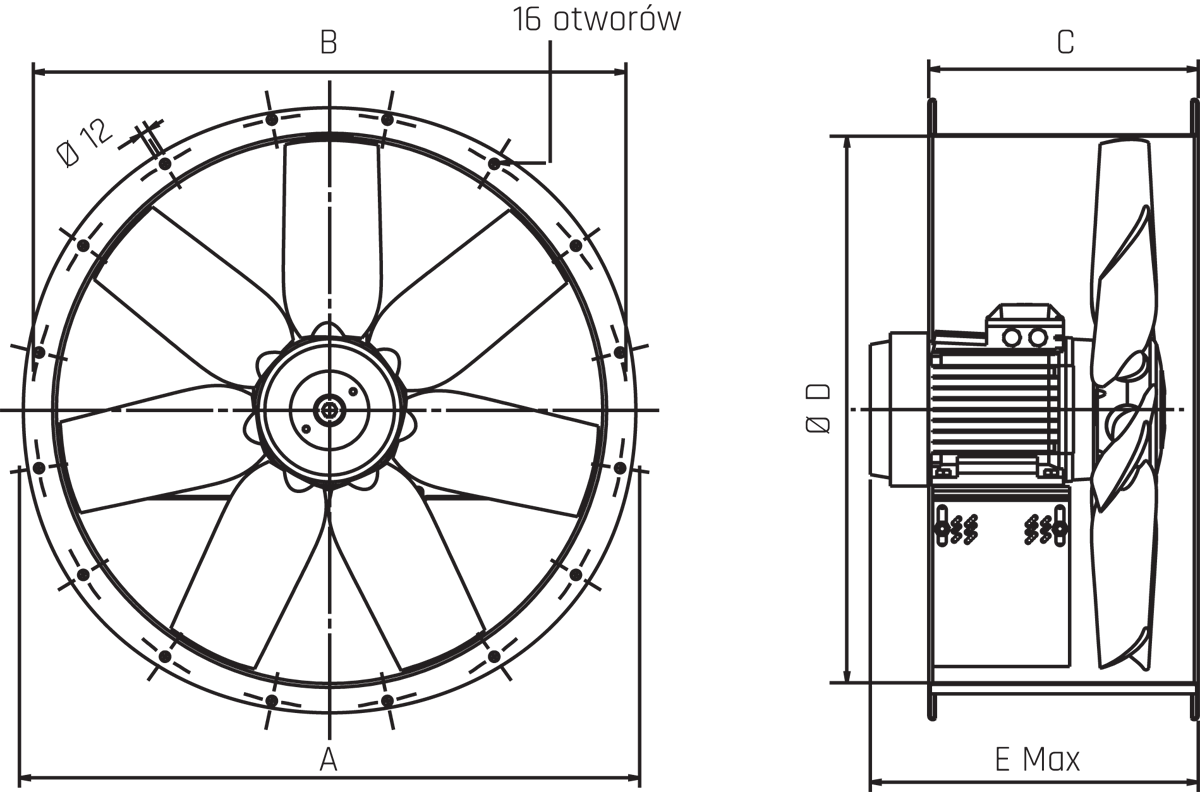

Dimensions

| Type | C | N | ØA | ØB | ØD | ØE |

|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | |

| TCBB/2-250/H | 170 | 4 | 327 | 292 | 254 | 10 |

| TCBB/4-250/H | 170 | 4 | 327 | 292 | 254 | 10 |

| TCBB/4-315/H | 170 | 8 | 386 | 355 | 315 | 10 |

| TCBB/4-355/H | 170 | 8 | 426 | 395 | 355 | 10 |

| TCBB/4-400/H | 210 | 8 | 487 | 450 | 400 | 12 |

| TCBB/6-355/H | 170 | 8 | 426 | 395 | 355 | 10 |

| TCBB/6-400/H | 170 | 8 | 487 | 450 | 400 | 12 |

| TCBT/2-250/H | 170 | 4 | 327 | 292 | 254 | 10 |

| TCBT/4-250/H | 170 | 4 | 327 | 292 | 254 | 10 |

| TCBT/4-315/H | 170 | 8 | 386 | 355 | 315 | 10 |

| TCBT/4-355/H | 170 | 8 | 426 | 395 | 355 | 10 |

| TCBT/4-400/H | 210 | 8 | 487 | 450 | 400 | 12 |

| TCBT/6-355/H | 170 | 8 | 426 | 395 | 355 | 10 |

| TCBT/6-400/H | 170 | 8 | 487 | 450 | 400 | 12 |

| Type | C | N | ØA | ØB | ØD | ØE |

|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | |

| TCBB/4-450/H | 180 | 8 | 537 | 500 | 450 | 12 |

| TCBB/4-500/H | 180 | 12 | 595 | 560 | 500 | 12 |

| TCBB/4-560/L | 240 | 12 | 655 | 620 | 560 | 12 |

| TCBB/4-560/H | 240 | 12 | 655 | 620 | 560 | 12 |

| TCBB/4-630/L | 240 | 12 | 725 | 690 | 630 | 12 |

| TCBB/6-500/H | 180 | 12 | 595 | 560 | 500 | 12 |

| TCBB/6-560/L | 240 | 12 | 655 | 620 | 560 | 12 |

| TCBB/6-630/L | 240 | 12 | 725 | 690 | 630 | 12 |

| TCBB/6-710/L | 240 | 16 | 806 | 770 | 710 | 12 |

| TCBT/4-450/H | 180 | 8 | 537 | 500 | 450 | 12 |

| TCBT/4-500/H | 180 | 12 | 595 | 560 | 500 | 12 |

| TCBT/4-560/L | 240 | 12 | 655 | 620 | 560 | 12 |

| TCBT/4-560/H | 240 | 12 | 655 | 620 | 560 | 12 |

| TCBT/4-630/L | 240 | 12 | 725 | 690 | 630 | 12 |

| TCBT/4-630/H | 240 | 12 | 725 | 690 | 630 | 12 |

| TCBT/6-450/H | 180 | 8 | 537 | 500 | 450 | 12 |

| TCBT/6-500/H | 180 | 12 | 595 | 560 | 500 | 12 |

| TCBT/6-560/H | 240 | 12 | 655 | 620 | 560 | 12 |

| TCBT/6-630/L | 240 | 12 | 725 | 690 | 630 | 12 |

| TCBT/6-630/H | 240 | 12 | 725 | 690 | 630 | 12 |

| TCBT/6-710/L | 240 | 16 | 806 | 770 | 710 | 12 |

| TCBT/6-710/H | 240 | 16 | 806 | 770 | 710 | 12 |

| Type | B | C | E | ØA | ØD |

|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | |

| TCBT/4-710/L | 770 | 380 | 415 | 806 | 710 |

| TCBT/4-710/H | 770 | 380 | 444 | 806 | 710 |

| TCBT/4-800/L | 860 | 380 | 437 | 896 | 800 |

| TCBT/4-800/K | 860 | 380 | 439 | 896 | 800 |

| TCBT/4-800/G | 860 | 380 | 447 | 896 | 800 |

| TCBT/4-800/H | 860 | 380 | 515 | 896 | 800 |

| TCBT/6-800/L | 860 | 380 | 408 | 896 | 800 |

| TCBT/6-800/K | 860 | 380 | 437 | 896 | 800 |

| TCBT/6-800/G | 860 | 380 | 448 | 896 | 800 |

| TCBT/6-800/H | 860 | 380 | 477 | 896 | 800 |

Additional equipment