Fan Selection Software

Operating point

Select fan type

GFB

Centrifugal fan

Low-pressure radial fan with direct drive, designed for transporting non-aggressive and non-explosive gases without pollution.

Can be painted in a color

other than standard

other than standard

APPLICATION

Fan designed for transporting non-aggressive and non-explosive gases without contomination. Typical applications:

- various mechanical ventilation installations,

- air pumping in production processes,

- cooling, drying systems,

- refrigeration and air-conditioning equipment,

- air handling units.

CONSTRUCTION

- low-pressure centrifugal fan with direct drive,

- the impeller is welded from galvanized steel sheet with forward curved blades, dynamically balanced according to ISO 1940-1, (stainless steel sheet 1.4301 for size 97),

- the housing is made of welded sheet steel,

- protective mesh at the inlet,

- motor stand in 250-400 models and in the 4/225 model,

- fan painted blue RAL 5010 (corrosivity category C3),

- maximum temperature of the transported medium is 80°C,

- ambient temperature range from -20°C to +40°C,

- figure LG90 in 4/250, 4/315 and 6/315 models,

- figure LG270 in other models.

MOTOR

- asynchronous single-phase 230V 50Hz (power to 1,1kW),

- asynchronous, three-phase 230V/400V 50Hz (power to 3kW)

- asynchronous, three-phase 400V/690V 50Hz (power from 5,5kW),

- efficiency class IE3 (power from 0,25kW), or IE1 (power to 0,25kW),

- degree of protection IP55,

- insulation class F,

- three-phase motors are adapted for frequency converter.

SPECIAL EXECUTIONS

- optional configuration LG/RD,

- color other than standard,

- painting in higher category of corrosivity,

- housing and support made of galvanized steel sheet,

- housing and support made of stainless steel 1.4301,

- housing and support made of acid-proof steel 1.4404,

- motor with voltage and frequency of power different than standard,

- motor with other than standard degree of protection,

- motor equipped with sensors or additional cooling,

- sealing between the housing and the motor,

- ambient temperature range below -20°C and above +40°C.

Technical assistance

Catalog card

- User manual 2,74 MB

- Declaration of conformity (CE) 546,76 KB

- Declaration of conformity (CE) 552,86 KB

- Declaration of conformity (CE) 429,86 KB

- Declaration of conformity (CE) 523,81 KB

- Declaration of conformity (CE) 514,79 KB

- CAD drawings 31,79 MB

- Electrical connection diagram 43,01 KB

- Electrical connection diagram 41,24 KB

Work characteristics

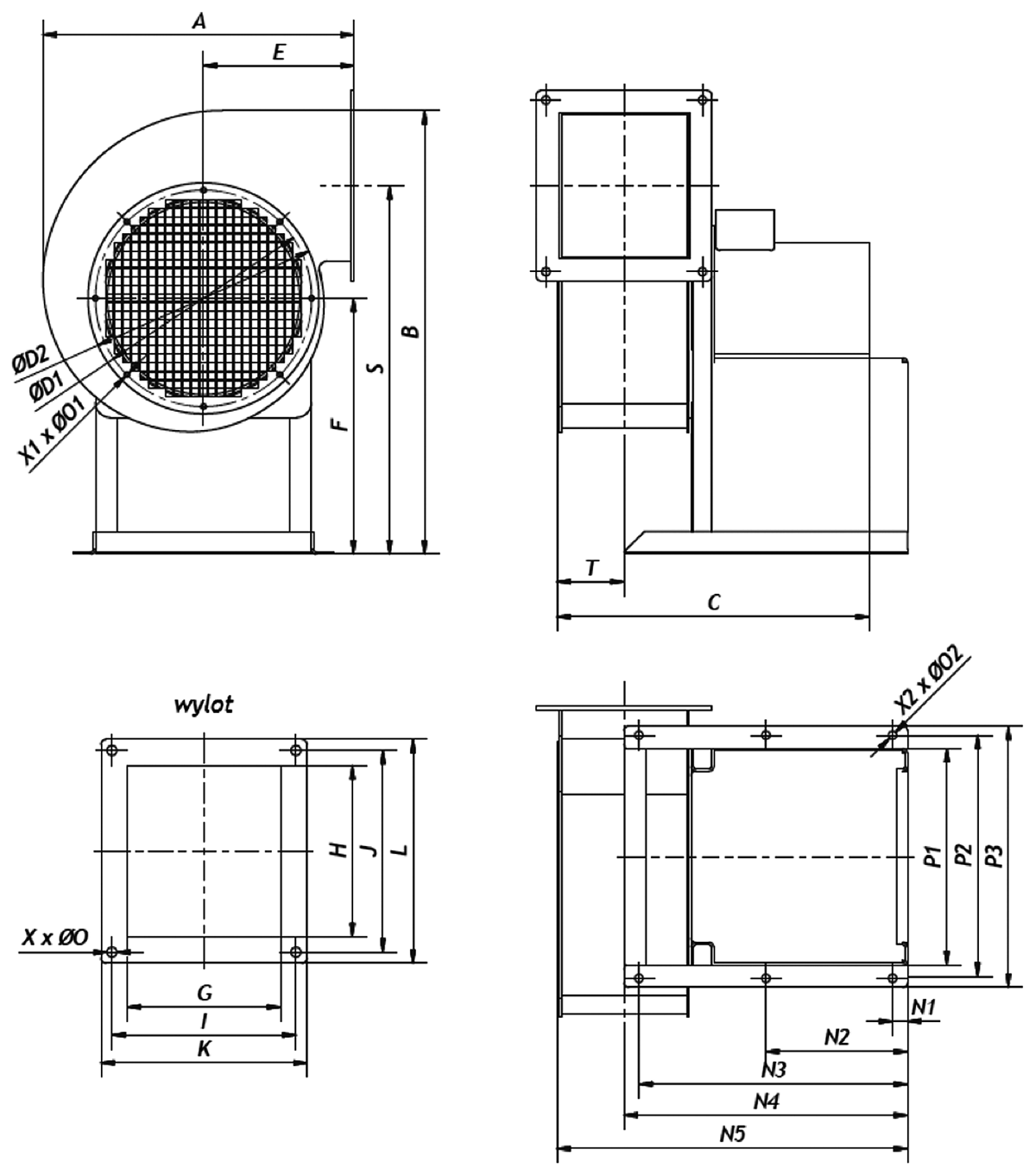

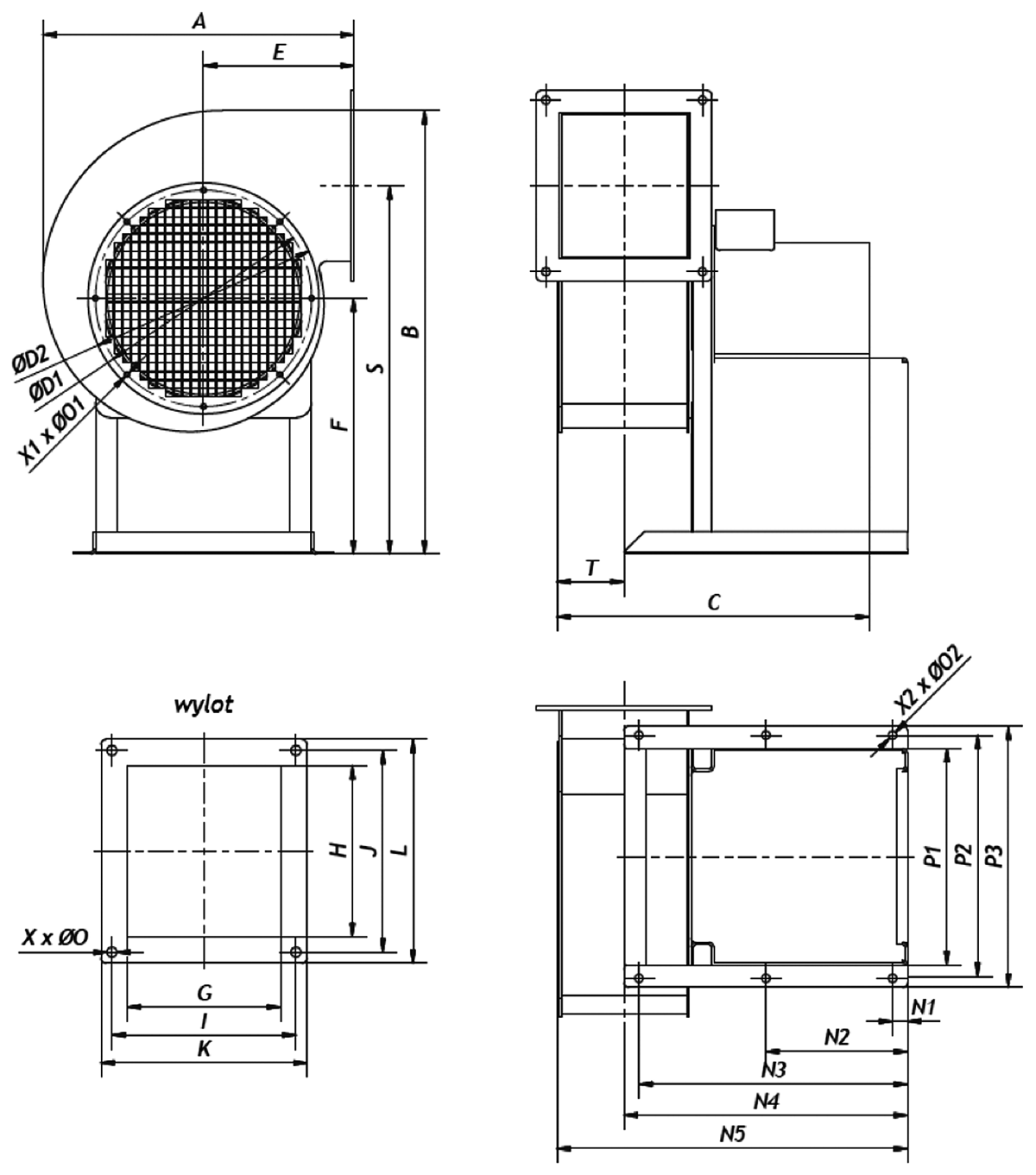

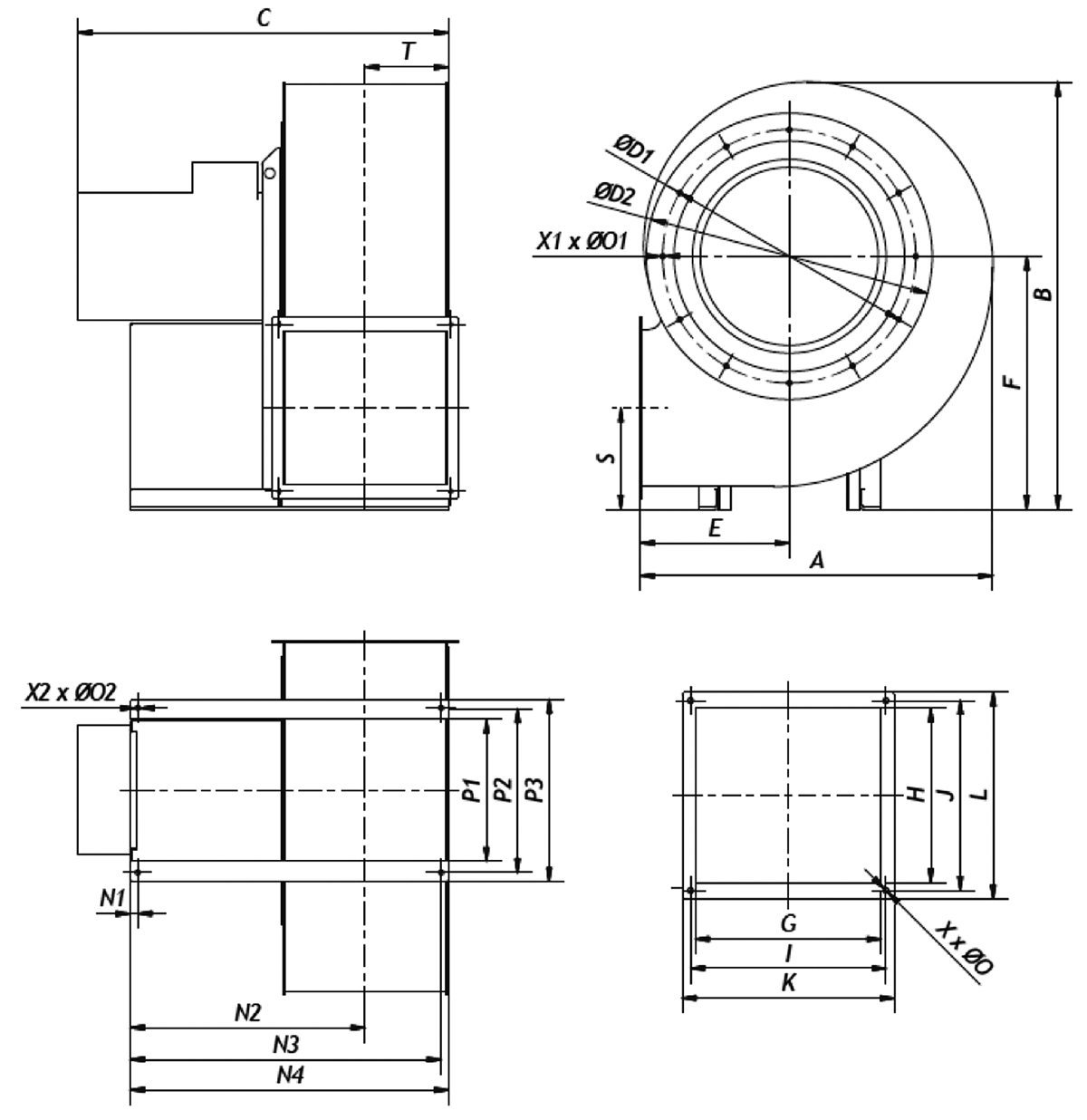

Dimensions

| Type | A | B | C | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-97/42-003S | 199 | 200 | 204 | 99 | 115 | 64 | 65 | 76 | 76 |

| GFB/2-97/42-005T | 199 | 200 | 204 | 99 | 115 | 64 | 65 | 76 | 76 |

| GFB/2-108/42-009T | 238 | 245 | 276 | 115 | 142 | 91 | 88 | 115 | 105 |

| GFB/2-133/62-018T | 238 | 245 | 276 | 115 | 142 | 91 | 88 | 115 | 105 |

| GFB/2-146/62-025S | 258 | 270 | 288 | 123 | 155 | 91 | 88 | 115 | 105 |

| GFB/2-146/62-025T | 258 | 270 | 288 | 123 | 155 | 91 | 88 | 115 | 105 |

| GFB/2-160/62-037S | 281 | 296 | 291 | 132 | 170 | 90 | 107 | 110 | 120 |

| GFB/2-160/62-037T | 281 | 296 | 291 | 132 | 170 | 90 | 107 | 110 | 120 |

| GFB/2-180/62-075S | 312 | 334 | 345 | 145 | 192 | 100 | 123 | 130 | 130 |

| GFB/2-180/62-075T | 312 | 334 | 345 | 145 | 192 | 100 | 123 | 130 | 130 |

| GFB/4-200/74-037T | 370 | 370 | 393 | 182 | 213 | 119 | 134 | 143 | 160 |

| GFB/2-200/74-110S | 370 | 370 | 393 | 182 | 213 | 119 | 134 | 143 | 160 |

| GFB/2-200/74-110T | 370 | 370 | 393 | 182 | 213 | 119 | 134 | 143 | 160 |

| GFB/2-225/104-300T | 374 | 382 | 462 | 182 | 217 | 148 | 136 | 173 | 161 |

| Type | K | L | O | S | T | X | D1 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-97/42-003S | 90 | 90 | 34 | 36 | 4 | ||

| GFB/2-97/42-005T | 90 | 90 | 34 | 36 | 4 | ||

| GFB/2-108/42-009T | 130 | 120 | 45 | 49 | 4 | ||

| GFB/2-133/62-018T | 130 | 120 | 45 | 49 | 4 | ||

| GFB/2-146/62-025S | 130 | 120 | 45 | 49 | 4 | ||

| GFB/2-146/62-025T | 130 | 120 | 45 | 49 | 4 | ||

| GFB/2-160/62-037S | 126 | 140 | 55 | 49 | 4 | ||

| GFB/2-160/62-037T | 126 | 140 | 55 | 49 | 4 | ||

| GFB/2-180/62-075S | 155 | 155 | 62 | 53 | 3 | ||

| GFB/2-180/62-075T | 155 | 155 | 62 | 53 | 3 | ||

| GFB/4-200/74-037T | 163 | 180 | 70 | 64 | 4 | ||

| GFB/2-200/74-110S | 163 | 180 | 70 | 64 | 4 | ||

| GFB/2-200/74-110T | 163 | 180 | 70 | 64 | 4 | ||

| GFB/2-225/104-300T | 193 | 181 | 74 | 78 | 4 |

| Type | D2 | O1 | X1 | ØO | ØD1 | ØD2 | ØO1 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-97/42-003S | 8 | 6 | 120 | 130 | 3 | ||

| GFB/2-97/42-005T | 8 | 6 | 120 | 130 | 3 | ||

| GFB/2-108/42-009T | 6 | 7 | 150 | 160 | 3 | ||

| GFB/2-133/62-018T | 6 | 7 | 150 | 160 | 3 | ||

| GFB/2-146/62-025S | 8 | 7 | 160 | 175 | 3 | ||

| GFB/2-146/62-025T | 8 | 7 | 160 | 175 | 3 | ||

| GFB/2-160/62-037S | 8 | 7 | 172 | 182 | 3 | ||

| GFB/2-160/62-037T | 8 | 7 | 172 | 182 | 3 | ||

| GFB/2-180/62-075S | 8 | 7 | 200 | 210 | 3 | ||

| GFB/2-180/62-075T | 8 | 7 | 200 | 210 | 3 | ||

| GFB/4-200/74-037T | 8 | 7 | 222 | 235 | 3 | ||

| GFB/2-200/74-110S | 8 | 7 | 222 | 235 | 3 | ||

| GFB/2-200/74-110T | 8 | 7 | 222 | 235 | 3 | ||

| GFB/2-225/104-300T | 8 | 11 | 250 | 280 | 6 |

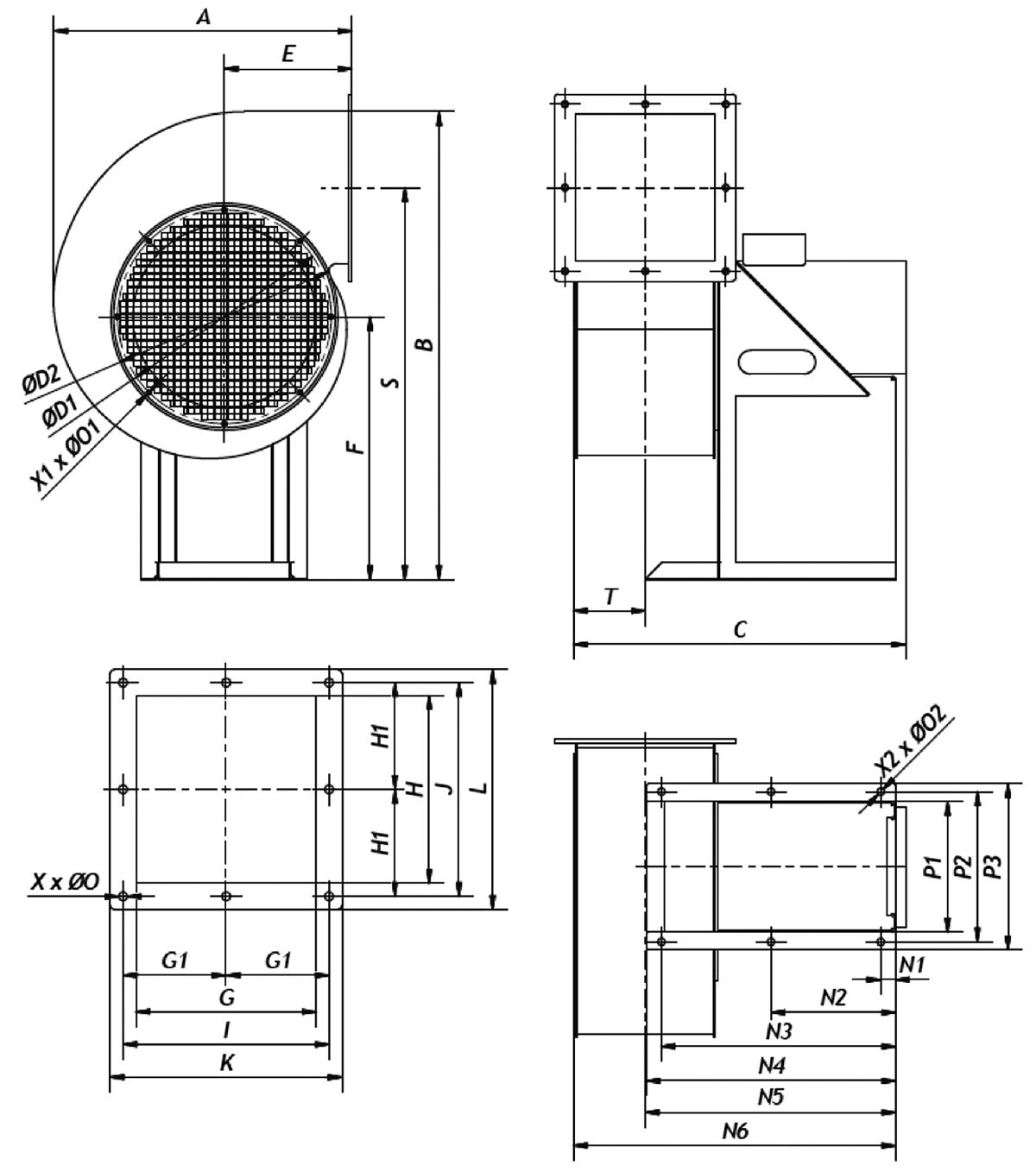

| Type | A | B | C | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-250/114-075S | 418 | 595 | 419 | 202 | 343 | 175 | 195 | 210 |

| GFB/4-250/114-075T | 418 | 595 | 419 | 202 | 343 | 175 | 195 | 210 |

| Type | J | K | L | S | T | X | N1 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-250/114-075S | 230 | 235 | 255 | 494 | 87 | 4 | 20 |

| GFB/4-250/114-075T | 230 | 235 | 255 | 494 | 87 | 4 | 20 |

| Type | N2 | N3 | N4 | N5 | P1 | P2 | P3 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-250/114-075S | 190 | 360 | 380 | 470 | 290 | 323 | 350 |

| GFB/4-250/114-075T | 190 | 360 | 380 | 470 | 290 | 323 | 350 |

| Type | X1 | X2 | ØO | ØD1 | ØD2 | ØO1 | ØO2 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-250/114-075S | 8 | 6 | 11 | 290 | 310 | 7 | 11 |

| GFB/4-250/114-075T | 8 | 6 | 11 | 290 | 310 | 7 | 11 |

| Type | A | B | C | E | F | G | H | I | J | K |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-250/114-550T | 418 | 522 | 538 | 202 | 343 | 175 | 195 | 210 | 230 | 235 |

| Type | L | O | S | T | X | D1 | D2 | N1 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-250/114-550T | 255 | 192 | 90 | 4 | 20 |

| Type | N2 | N3 | N4 | N5 | O1 | O2 | P1 | P2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-250/114-550T | 190 | 360 | 380 | 470 | 290 | 326 |

| Type | P3 | X1 | X2 | ØO | ØD1 | ØD2 | ØO1 | ØO2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/2-250/114-550T | 350 | 8 | 6 | 11 | 290 | 310 | 7 | 11 |

| Type | A | B | C | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-315/143-300T | 502 | 789 | 552 | 215 | 443 | 237 | 247 | 271 | 281 |

| Type | K | L | N | S | T | X | G1 | H1 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-315/143-300T | 305 | 315 | 660 | 121 | 8 | 136 | 140 |

| Type | N1 | N2 | N3 | N4 | N5 | N6 | P1 | P2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-315/143-300T | 25 | 210 | 395 | 420 | 422 | 543 | 220 | 253 |

| Type | P3 | X1 | X2 | ØO | ØD1 | ØD2 | ØO1 | ØO2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/4-315/143-300T | 280 | 7 | 6 | 11 | 360 | 374 | 6 | 12 |

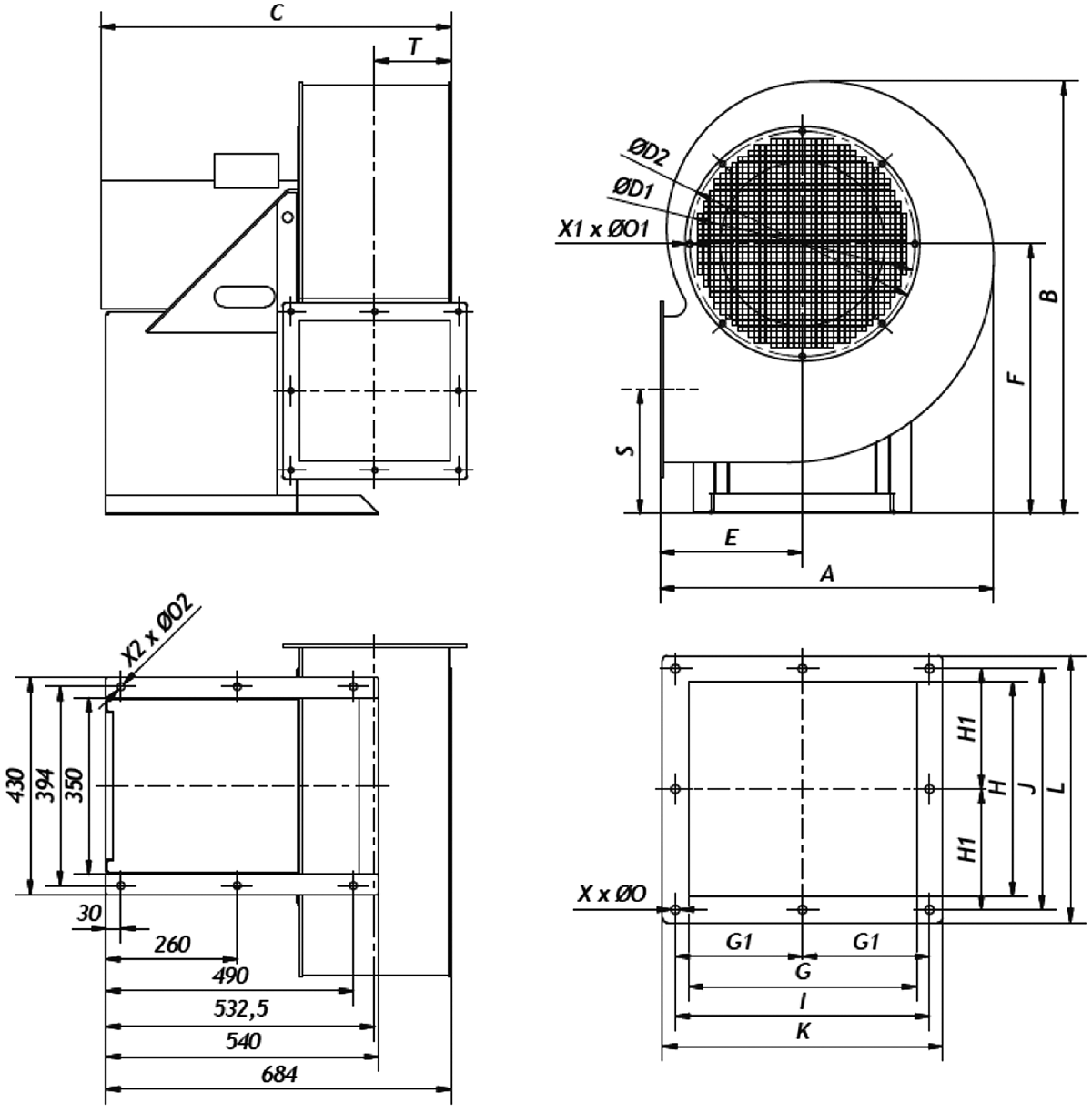

| Type | A | B | C | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-400/183-220T | 661 | 858 | 695 | 282 | 535 | 298 | 281 | 332 |

| GFB/4-400/183-750T | 661 | 858 | 695 | 282 | 535 | 298 | 281 | 332 |

| Type | J | K | L | S | T | X | G1 | H1 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-400/183-220T | 315 | 366 | 349 | 246 | 152 | 8 | 166 | 158 |

| GFB/4-400/183-750T | 315 | 366 | 349 | 246 | 152 | 8 | 166 | 158 |

| Type | N1 | N2 | N3 | N4 | N5 | N6 | P1 | P2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-400/183-220T | 30 | 260 | 490 | 532 | 540 | 684 | 350 | 394 |

| GFB/4-400/183-750T | 30 | 260 | 490 | 532 | 540 | 684 | 350 | 394 |

| Type | P3 | X1 | X2 | ØO | ØD1 | ØD2 | ØO1 | ØO2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-400/183-220T | 430 | 8 | 6 | 11 | 446 | 465 | 9 | 14 |

| GFB/4-400/183-750T | 430 | 8 | 6 | 11 | 446 | 465 | 9 | 14 |

| Type | A | B | C | E | F | G | H |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-450/203-550T | 697 | 844 | 732 | 295 | 500 | 323 | 303 |

| Type | I | J | K | L | S | T | X |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-450/203-550T | 340 | 330 | 369 | 360 | 200 | 164 | 4 |

| Type | N1 | N2 | N3 | N4 | P1 | P2 | P3 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-450/203-550T | 15 | 464 | 615 | 630 | 280 | 324 | 360 |

| Type | X1 | X2 | ØO | ØD1 | ØD2 | ØO1 | ØO2 |

|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | |

| GFB/6-450/203-550T | 12 | 4 | 9 | 500 | 565 | 9 | 10 |

Additional equipment