Fan Selection Software

Operating point

Select fan type

GMBv2

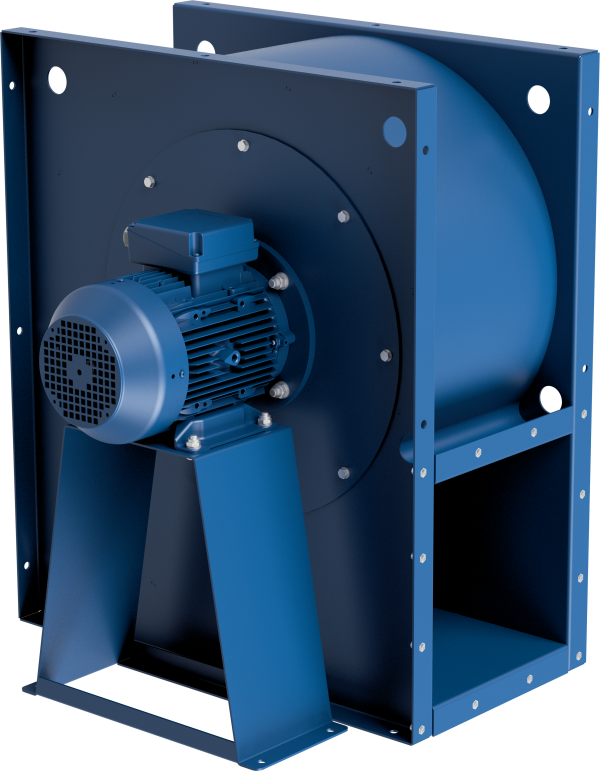

Centrifugal fan

Medium pressure, radial fan with direct drive. Designed for transporting slightly polluted air. Typical applications are: air conveying in technological processes, cooling systems and air drying systems.

Can be painted in a color

other than standard

other than standard

APPLICATION

Industrial fan designed to transfer clean or slightly contaminated, neutrally chemical air. Typical applications:

- air pressing in technological processes,

- cooling systems,

- air drying systems.

CONSTRUCTION

- medium-pressure, direct drive, radial fan,

- aluminum sheet rotor with backward inclined blades, balanced according to ISO 1940-1,

- rectangular steel welded housing,

- painted RAL 5010 (blue), corrosivity category C3,

- medium maximum temperature 80°C,

- ambient temperature of the motor from -20°C to 40°C,

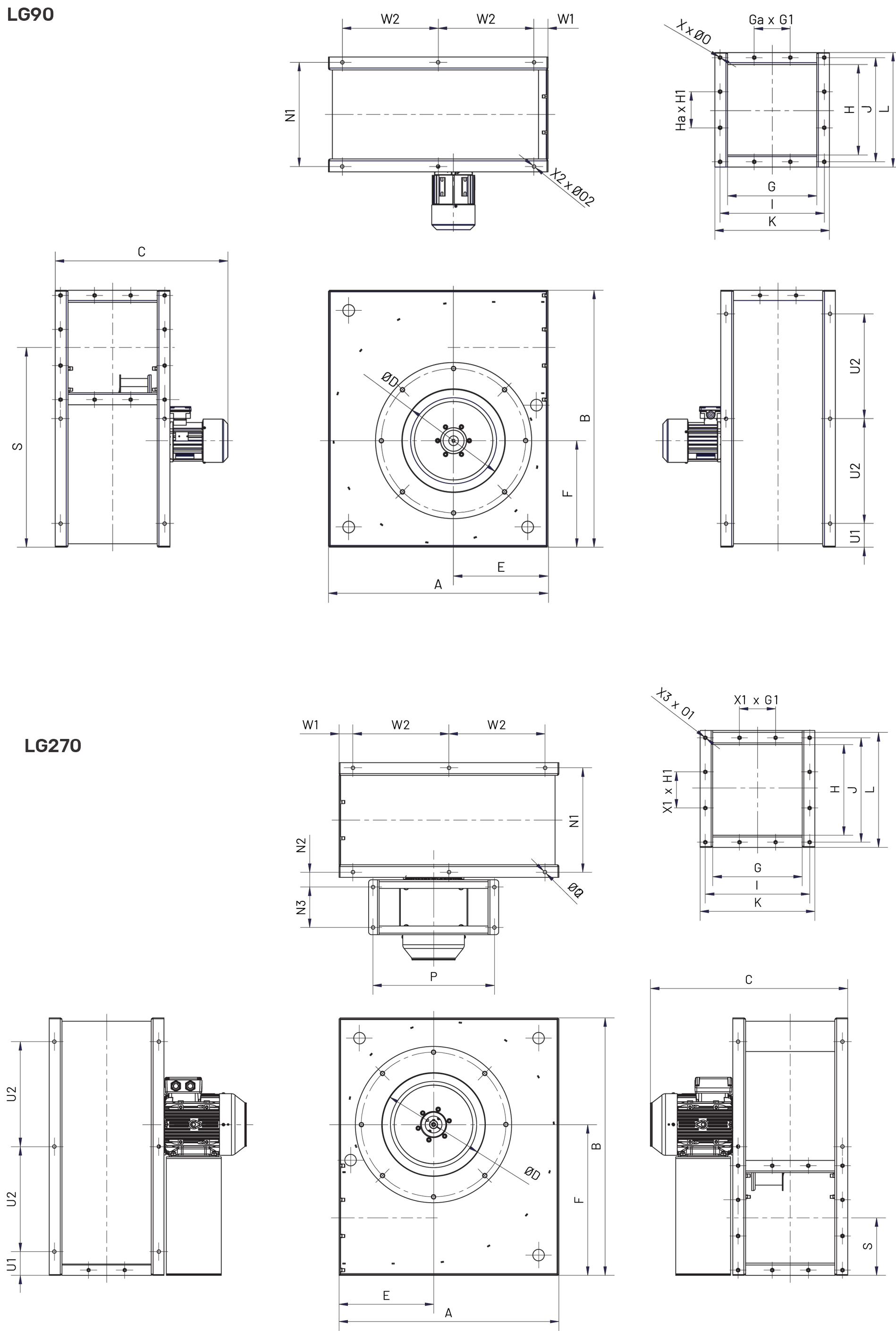

- depending on the motor power, the fans are standard in two figures LG90 and LG270 (see specifications table)

MOTOR

- asynchronous, three-phase 230V/400V 50Hz or 400/690V 50Hz, efficiency class IE3

- degree of protection IP55,

- insulation class F,

- three-phase motors are adapted for frequency converter.

SPECIAL EXECUTIONS

- optionol configuration LG/RD,

- color other than standard and higher category of corrosivity,

- housing and support made of galvanized steel sheet, stainless steel 1.4301, acid-proof steel 1.4404,

- motor with voltage and frequency of power, degree of protection different than standard, equipped with sensors or additional cooling,

- sealing between the housing and the motor,

- HT version - maximum transported medium temperature higher than standard,

- ambient temperature range below -20°C and above 40°C,

- belt drive, clutch,

- ATEX version

Technical assistance

Work characteristics

Dimensions

| Type | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GMB-2-25A-018T | 425 | 505 | 395 | 200 | 177 | 212 | 175 | 175 |

| GMB-2-25B-025T | 425 | 505 | 395 | 200 | 177 | 212 | 175 | 175 |

| GMB-2-25C-037T | 425 | 505 | 395 | 200 | 177 | 212 | 175 | 175 |

| GMB-2-28A-037T | 475 | 565 | 474 | 225 | 202 | 236 | 200 | 200 |

| GMB-2-28B-055T | 475 | 565 | 474 | 225 | 202 | 236 | 200 | 200 |

| GMB-2-28C-055T | 475 | 565 | 474 | 225 | 202 | 236 | 200 | 200 |

| GMB-2-31A-055T | 535 | 630 | 520 | 253 | 227 | 263 | 216 | 222 |

| GMB-2-31B-075T | 535 | 630 | 520 | 253 | 227 | 263 | 216 | 222 |

| GMB-2-31C-110T | 535 | 630 | 520 | 253 | 227 | 263 | 216 | 222 |

| GMB-2-35A-110T | 600 | 705 | 579 | 283 | 257 | 295 | 244 | 248 |

| GMB-2-35B-150T | 600 | 705 | 579 | 283 | 257 | 295 | 244 | 248 |

| GMB-2-35C-220T | 600 | 705 | 579 | 283 | 257 | 295 | 244 | 248 |

| GMB-2-40A-150T | 675 | 800 | 624 | 318 | 287 | 332 | 274 | 278 |

| GMB-2-40B-220T | 675 | 800 | 624 | 318 | 287 | 332 | 274 | 278 |

| GMB-2-40C-300T | 675 | 800 | 624 | 318 | 287 | 332 | 274 | 278 |

| GMB-2-45A-300T | 760 | 890 | 626 | 358 | 327 | 369 | 309 | 313 |

| GMB-2-45B-400T | 760 | 890 | 626 | 358 | 327 | 369 | 309 | 313 |

| GMB-2-45C-550T | 760 | 890 | 626 | 358 | 327 | 369 | 309 | 313 |

| GMB-2-50A-550T | 840 | 990 | 694 | 404 | 357 | 416 | 349 | 353 |

| GMB-2-50B-750T | 840 | 990 | 694 | 404 | 357 | 416 | 349 | 353 |

| GMB-2-50C-1100T | 840 | 990 | 694 | 404 | 357 | 416 | 349 | 353 |

| GMB-2-56A-1100T | 940 | 1110 | 738 | 454 | 397 | 472 | 394 | 398 |

| GMB-2-56B-1500T | 940 | 1110 | 738 | 454 | 397 | 472 | 394 | 398 |

| GMB-2-56C-1850T | 940 | 1110 | 738 | 454 | 397 | 472 | 394 | 398 |

| GMB-2-63A-1850T | 1060 | 1230 | 1167 | 504 | 447 | 713 | 444 | 448 |

| GMB-2-63B-2200T | 1060 | 1230 | 1167 | 504 | 447 | 713 | 444 | 448 |

| GMB-2-63C-3000T | 1060 | 1230 | 1167 | 504 | 447 | 713 | 444 | 448 |

| GMB-4-35A-012T | 600 | 705 | 579 | 283 | 257 | 295 | 244 | 248 |

| GMB-4-35B-018T | 600 | 705 | 579 | 283 | 257 | 295 | 244 | 248 |

| GMB-4-35C-025T | 600 | 705 | 579 | 283 | 257 | 295 | 244 | 248 |

| GMB-4-40A-018T | 675 | 790 | 592 | 318 | 287 | 332 | 274 | 278 |

| GMB-4-40B-025T | 675 | 790 | 592 | 318 | 287 | 332 | 274 | 278 |

| GMB-4-40C-037T | 675 | 790 | 592 | 318 | 287 | 332 | 274 | 278 |

| GMB-4-45A-037T | 760 | 890 | 626 | 358 | 327 | 369 | 309 | 313 |

| GMB-4-45B-055T | 760 | 890 | 626 | 358 | 327 | 369 | 309 | 313 |

| GMB-4-45C-075T | 760 | 890 | 626 | 358 | 327 | 369 | 309 | 313 |

| GMB-4-50A-075T | 840 | 990 | 694 | 404 | 357 | 416 | 349 | 353 |

| GMB-4-50B-110T | 840 | 990 | 694 | 404 | 357 | 416 | 349 | 353 |

| GMB-4-50C-150T | 840 | 990 | 694 | 404 | 357 | 416 | 349 | 353 |

| GMB-4-56A-110T | 940 | 1110 | 738 | 454 | 397 | 472 | 394 | 398 |

| GMB-4-56B-150T | 940 | 1110 | 738 | 454 | 397 | 472 | 394 | 398 |

| GMB-4-56C-220T | 940 | 1110 | 738 | 454 | 397 | 472 | 394 | 398 |

| GMB-4-63A-220T | 1060 | 1230 | 1167 | 504 | 447 | 713 | 444 | 448 |

| GMB-4-63B-300T | 1060 | 1230 | 1167 | 504 | 447 | 713 | 444 | 448 |

| GMB-4-63C-400T | 1060 | 1230 | 1167 | 504 | 447 | 713 | 444 | 448 |

| GMB-4-71A-400T | 1190 | 1390 | 830 | 564 | 507 | 588 | 492 | 498 |

| GMB-4-71B-550T | 1190 | 1390 | 830 | 564 | 507 | 588 | 492 | 498 |

| GMB-4-71C-750T | 1190 | 1390 | 830 | 564 | 507 | 588 | 492 | 498 |

| GMB-4-80A-750T | 1350 | 1560 | 1099 | 634 | 580 | 898 | 552 | 558 |

| GMB-4-80B-1100T | 1350 | 1560 | 1099 | 634 | 580 | 898 | 552 | 558 |

| GMB-4-80C-1500T | 1350 | 1560 | 1099 | 634 | 580 | 898 | 552 | 558 |

| GMB-6-71A-110T | 1190 | 1390 | 830 | 564 | 507 | 588 | 492 | 498 |

| GMB-6-71B-150T | 1190 | 1390 | 830 | 564 | 507 | 588 | 492 | 498 |

| GMB-6-71C-220T | 1190 | 1390 | 830 | 564 | 507 | 588 | 492 | 498 |

| GMB-6-80A-220T | 1350 | 1560 | 1099 | 634 | 580 | 898 | 552 | 558 |

| GMB-6-80B-300T | 1350 | 1560 | 1099 | 634 | 580 | 898 | 552 | 558 |

| GMB-6-80C-400T | 1350 | 1560 | 1099 | 634 | 580 | 898 | 552 | 558 |

| Type | I | J | K | L | O | P | S | X |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GMB-2-25A-018T | 216 | 216 | 229 | 229 | M6 | - | 391 | 12 |

| GMB-2-25B-025T | 216 | 216 | 229 | 229 | M6 | - | 391 | 12 |

| GMB-2-25C-037T | 216 | 216 | 229 | 229 | M6 | - | 391 | 12 |

| GMB-2-28A-037T | 236 | 236 | 262 | 262 | M6 | - | 434 | 12 |

| GMB-2-28B-055T | 236 | 236 | 262 | 262 | M6 | - | 434 | 12 |

| GMB-2-28C-055T | 236 | 236 | 262 | 262 | M6 | - | 434 | 12 |

| GMB-2-31A-055T | 260 | 260 | 286 | 286 | M8 | - | 487 | 12 |

| GMB-2-31B-075T | 260 | 260 | 286 | 286 | M8 | - | 487 | 12 |

| GMB-2-31C-110T | 260 | 260 | 286 | 286 | M8 | - | 487 | 12 |

| GMB-2-35A-110T | 286 | 286 | 312 | 312 | M8 | - | 549 | 12 |

| GMB-2-35B-150T | 286 | 286 | 312 | 312 | M8 | - | 549 | 12 |

| GMB-2-35C-220T | 286 | 286 | 312 | 312 | M8 | - | 549 | 12 |

| GMB-2-40A-150T | 326 | 326 | 362 | 362 | M8 | - | 619 | 12 |

| GMB-2-40B-220T | 326 | 326 | 362 | 362 | M8 | - | 619 | 12 |

| GMB-2-40C-300T | 326 | 326 | 362 | 362 | M8 | - | 619 | 12 |

| GMB-2-45A-300T | 361 | 361 | 397 | 397 | M8 | 199 | 692 | 12 |

| GMB-2-45B-400T | 361 | 361 | 397 | 397 | M8 | 199 | 692 | 12 |

| GMB-2-45C-550T | 361 | 361 | 397 | 397 | M8 | 199 | 692 | 12 |

| GMB-2-50A-550T | 401 | 401 | 437 | 437 | M10 | 219 | 772 | 12 |

| GMB-2-50B-750T | 401 | 401 | 437 | 437 | M10 | 219 | 772 | 12 |

| GMB-2-50C-1100T | 401 | 401 | 437 | 437 | M10 | 219 | 772 | 12 |

| GMB-2-56A-1100T | 446 | 446 | 482 | 482 | M10 | 241 | 869 | 12 |

| GMB-2-56B-1500T | 446 | 446 | 482 | 482 | M10 | 241 | 869 | 12 |

| GMB-2-56C-1850T | 446 | 446 | 482 | 482 | M10 | 241 | 869 | 12 |

| GMB-2-63A-1850T | 496 | 496 | 532 | 496 | M10 | 266 | 82 | 20 |

| GMB-2-63B-2200T | 496 | 496 | 532 | 496 | M10 | 266 | 82 | 20 |

| GMB-2-63C-3000T | 496 | 496 | 532 | 496 | M10 | 266 | 82 | 20 |

| GMB-4-35A-012T | 286 | 286 | 312 | 312 | M8 | - | 549 | 12 |

| GMB-4-35B-018T | 286 | 286 | 312 | 312 | M8 | - | 549 | 12 |

| GMB-4-35C-025T | 286 | 286 | 312 | 312 | M8 | - | 549 | 12 |

| GMB-4-40A-018T | 326 | 326 | 362 | 362 | M8 | - | 609 | 12 |

| GMB-4-40B-025T | 326 | 326 | 362 | 362 | M8 | - | 609 | 12 |

| GMB-4-40C-037T | 326 | 326 | 362 | 362 | M8 | - | 609 | 12 |

| GMB-4-45A-037T | 361 | 361 | 397 | 397 | M8 | 199 | 692 | 12 |

| GMB-4-45B-055T | 361 | 361 | 397 | 397 | M8 | 199 | 692 | 12 |

| GMB-4-45C-075T | 361 | 361 | 397 | 397 | M8 | 199 | 692 | 12 |

| GMB-4-50A-075T | 401 | 401 | 437 | 437 | M10 | 219 | 772 | 12 |

| GMB-4-50B-110T | 401 | 401 | 437 | 437 | M10 | 219 | 772 | 12 |

| GMB-4-50C-150T | 401 | 401 | 437 | 437 | M10 | 219 | 772 | 12 |

| GMB-4-56A-110T | 446 | 446 | 482 | 482 | M10 | 241 | 869 | 12 |

| GMB-4-56B-150T | 446 | 446 | 482 | 482 | M10 | 241 | 869 | 12 |

| GMB-4-56C-220T | 446 | 446 | 482 | 482 | M10 | 241 | 869 | 12 |

| GMB-4-63A-220T | 496 | 496 | 532 | 496 | M10 | 266 | 82 | 20 |

| GMB-4-63B-300T | 496 | 496 | 532 | 496 | M10 | 266 | 82 | 20 |

| GMB-4-63C-400T | 496 | 496 | 532 | 496 | M10 | 266 | 82 | 20 |

| GMB-4-71A-400T | 546 | 546 | 586 | 590 | M12 | 295 | 1095 | 20 |

| GMB-4-71B-550T | 546 | 546 | 586 | 590 | M12 | 295 | 1095 | 20 |

| GMB-4-71C-750T | 546 | 546 | 586 | 590 | M12 | 295 | 1095 | 20 |

| GMB-4-80A-750T | 606 | 606 | 646 | 606 | M12 | 325 | 82 | 20 |

| GMB-4-80B-1100T | 606 | 606 | 646 | 606 | M12 | 325 | 82 | 20 |

| GMB-4-80C-1500T | 606 | 606 | 646 | 606 | M12 | 325 | 82 | 20 |

| GMB-6-71A-110T | 546 | 546 | 586 | 590 | M12 | 295 | 1095 | 20 |

| GMB-6-71B-150T | 546 | 546 | 586 | 590 | M12 | 295 | 1095 | 20 |

| GMB-6-71C-220T | 546 | 546 | 586 | 590 | M12 | 295 | 1095 | 20 |

| GMB-6-80A-220T | 606 | 606 | 646 | 606 | M12 | 325 | 82 | 20 |

| GMB-6-80B-300T | 606 | 606 | 646 | 606 | M12 | 325 | 82 | 20 |

| GMB-6-80C-400T | 606 | 606 | 646 | 606 | M12 | 325 | 82 | 20 |

| Type | D1 | G1 | Ga | H1 | Ha | N1 | N2 | N3 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GMB-2-25A-018T | 300 | 100 | 1 | 100 | 1 | 216 | - | - |

| GMB-2-25B-025T | 300 | 100 | 1 | 100 | 1 | 216 | - | - |

| GMB-2-25C-037T | 300 | 100 | 1 | 100 | 1 | 216 | - | - |

| GMB-2-28A-037T | 325 | 100 | 1 | 100 | 1 | 236 | - | - |

| GMB-2-28B-055T | 325 | 100 | 1 | 100 | 1 | 236 | - | - |

| GMB-2-28C-055T | 325 | 100 | 1 | 100 | 1 | 236 | - | - |

| GMB-2-31A-055T | 350 | 100 | 1 | 100 | 1 | 260 | - | - |

| GMB-2-31B-075T | 350 | 100 | 1 | 100 | 1 | 260 | - | - |

| GMB-2-31C-110T | 350 | 100 | 1 | 100 | 1 | 260 | - | - |

| GMB-2-35A-110T | 400 | 125 | 1 | 125 | 1 | 286 | - | - |

| GMB-2-35B-150T | 400 | 125 | 1 | 125 | 1 | 286 | - | - |

| GMB-2-35C-220T | 400 | 125 | 1 | 125 | 1 | 286 | - | - |

| GMB-2-40A-150T | 460 | 125 | 1 | 125 | 1 | 326 | - | - |

| GMB-2-40B-220T | 460 | 125 | 1 | 125 | 1 | 326 | - | - |

| GMB-2-40C-300T | 460 | 125 | 1 | 125 | 1 | 326 | - | - |

| GMB-2-45A-300T | 500 | 125 | 1 | 125 | 1 | 361 | 140 | 420 |

| GMB-2-45B-400T | 500 | 125 | 1 | 125 | 1 | 361 | 140 | 420 |

| GMB-2-45C-550T | 500 | 125 | 1 | 125 | 1 | 361 | 140 | 420 |

| GMB-2-50A-550T | 550 | 125 | 1 | 125 | 1 | 401 | 160 | 500 |

| GMB-2-50B-750T | 550 | 125 | 1 | 125 | 1 | 401 | 160 | 500 |

| GMB-2-50C-1100T | 550 | 125 | 1 | 125 | 1 | 401 | 160 | 500 |

| GMB-2-56A-1100T | 620 | 125 | 1 | 125 | 1 | 446 | 180 | 540 |

| GMB-2-56B-1500T | 620 | 125 | 1 | 125 | 1 | 446 | 180 | 540 |

| GMB-2-56C-1850T | 620 | 125 | 1 | 125 | 1 | 446 | 180 | 540 |

| GMB-2-63A-1850T | 700 | 125 | 3 | 125 | 3 | 51 | 200 | 560 |

| GMB-2-63B-2200T | 700 | 125 | 3 | 125 | 3 | 51 | 200 | 560 |

| GMB-2-63C-3000T | 700 | 125 | 3 | 125 | 3 | 51 | 200 | 560 |

| GMB-4-35A-012T | 400 | 125 | 1 | 125 | 1 | 286 | - | - |

| GMB-4-35B-018T | 400 | 125 | 1 | 125 | 1 | 286 | - | - |

| GMB-4-35C-025T | 400 | 125 | 1 | 125 | 1 | 286 | - | - |

| GMB-4-40A-018T | 460 | 125 | 1 | 125 | 1 | 326 | - | - |

| GMB-4-40B-025T | 460 | 125 | 1 | 125 | 1 | 326 | - | - |

| GMB-4-40C-037T | 460 | 125 | 1 | 125 | 1 | 326 | - | - |

| GMB-4-45A-037T | 500 | 125 | 1 | 125 | 1 | 361 | 140 | 420 |

| GMB-4-45B-055T | 500 | 125 | 1 | 125 | 1 | 361 | 140 | 420 |

| GMB-4-45C-075T | 500 | 125 | 1 | 125 | 1 | 361 | 140 | 420 |

| GMB-4-50A-075T | 550 | 125 | 1 | 125 | 1 | 401 | 160 | 500 |

| GMB-4-50B-110T | 550 | 125 | 1 | 125 | 1 | 401 | 160 | 500 |

| GMB-4-50C-150T | 550 | 125 | 1 | 125 | 1 | 401 | 160 | 500 |

| GMB-4-56A-110T | 620 | 125 | 1 | 125 | 1 | 446 | 180 | 540 |

| GMB-4-56B-150T | 620 | 125 | 1 | 125 | 1 | 446 | 180 | 540 |

| GMB-4-56C-220T | 620 | 125 | 1 | 125 | 1 | 446 | 180 | 540 |

| GMB-4-63A-220T | 700 | 125 | 3 | 125 | 3 | 51 | 200 | 560 |

| GMB-4-63B-300T | 700 | 125 | 3 | 125 | 3 | 51 | 200 | 560 |

| GMB-4-63C-400T | 700 | 125 | 3 | 125 | 3 | 51 | 200 | 560 |

| GMB-4-71A-400T | 790 | 125 | 3 | 125 | 3 | 546 | 130 | 560 |

| GMB-4-71B-550T | 790 | 125 | 3 | 125 | 3 | 546 | 130 | 560 |

| GMB-4-71C-750T | 790 | 125 | 3 | 125 | 3 | 546 | 130 | 560 |

| GMB-4-80A-750T | 880 | 125 | 3 | 125 | 3 | 58 | 150 | 580 |

| GMB-4-80B-1100T | 880 | 125 | 3 | 125 | 3 | 58 | 150 | 580 |

| GMB-4-80C-1500T | 880 | 125 | 3 | 125 | 3 | 58 | 150 | 580 |

| GMB-6-71A-110T | 790 | 125 | 3 | 125 | 3 | 546 | 130 | 560 |

| GMB-6-71B-150T | 790 | 125 | 3 | 125 | 3 | 546 | 130 | 560 |

| GMB-6-71C-220T | 790 | 125 | 3 | 125 | 3 | 546 | 130 | 560 |

| GMB-6-80A-220T | 880 | 125 | 3 | 125 | 3 | 58 | 150 | 580 |

| GMB-6-80B-300T | 880 | 125 | 3 | 125 | 3 | 58 | 150 | 580 |

| GMB-6-80C-400T | 880 | 125 | 3 | 125 | 3 | 58 | 150 | 580 |

| Type | O1 | O2 | U1 | U2 | W1 | W2 | X1 | X2 |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | |

| GMB-2-25A-018T | M6 | 10 | 82 | 341 | 48 | 329 | 8 | 4 |

| GMB-2-25B-025T | M6 | 10 | 82 | 341 | 48 | 329 | 8 | 4 |

| GMB-2-25C-037T | M6 | 10 | 82 | 341 | 48 | 329 | 8 | 4 |

| GMB-2-28A-037T | M6 | 10 | 82 | 401 | 48 | 379 | 8 | 4 |

| GMB-2-28B-055T | M6 | 10 | 82 | 401 | 48 | 379 | 8 | 4 |

| GMB-2-28C-055T | M6 | 10 | 82 | 401 | 48 | 379 | 8 | 4 |

| GMB-2-31A-055T | M6 | 10 | 82 | 466 | 48 | 439 | 8 | 6 |

| GMB-2-31B-075T | M6 | 10 | 82 | 466 | 48 | 439 | 8 | 6 |

| GMB-2-31C-110T | M6 | 10 | 82 | 466 | 48 | 439 | 8 | 6 |

| GMB-2-35A-110T | M6 | 10 | 82 | 541 | 48 | 504 | 8 | 6 |

| GMB-2-35B-150T | M6 | 10 | 82 | 541 | 48 | 504 | 8 | 6 |

| GMB-2-35C-220T | M6 | 10 | 82 | 541 | 48 | 504 | 8 | 6 |

| GMB-2-40A-150T | M8 | 10 | 82 | 318 | 48 | 290 | 8 | 6 |

| GMB-2-40B-220T | M8 | 10 | 82 | 318 | 48 | 290 | 8 | 6 |

| GMB-2-40C-300T | M8 | 10 | 82 | 318 | 48 | 290 | 8 | 6 |

| GMB-2-45A-300T | M8 | 12 | 82 | 363 | 48 | 332 | 8 | 6 |

| GMB-2-45B-400T | M8 | 12 | 82 | 363 | 48 | 332 | 8 | 6 |

| GMB-2-45C-550T | M8 | 12 | 82 | 363 | 48 | 332 | 8 | 6 |

| GMB-2-50A-550T | M8 | 12 | 82 | 413 | 48 | 372 | 12 | 6 |

| GMB-2-50B-750T | M8 | 12 | 82 | 413 | 48 | 372 | 12 | 6 |

| GMB-2-50C-1100T | M8 | 12 | 82 | 413 | 48 | 372 | 12 | 6 |

| GMB-2-56A-1100T | M8 | 12 | 82 | 473 | 48 | 422 | 12 | 6 |

| GMB-2-56B-1500T | M8 | 12 | 82 | 473 | 48 | 422 | 12 | 6 |

| GMB-2-56C-1850T | M8 | 12 | 82 | 473 | 48 | 422 | 12 | 6 |

| GMB-2-63A-1850T | M10 | 12 | 533 | 48 | 482 | 504 | 12 | 6 |

| GMB-2-63B-2200T | M10 | 12 | 533 | 48 | 482 | 504 | 12 | 6 |

| GMB-2-63C-3000T | M10 | 12 | 533 | 48 | 482 | 504 | 12 | 6 |

| GMB-4-35A-012T | M6 | 10 | 82 | 541 | 48 | 504 | 8 | 6 |

| GMB-4-35B-018T | M6 | 10 | 82 | 541 | 48 | 504 | 8 | 6 |

| GMB-4-35C-025T | M6 | 10 | 82 | 541 | 48 | 504 | 8 | 6 |

| GMB-4-40A-018T | M8 | 10 | 82 | 313 | 48 | 290 | 8 | 6 |

| GMB-4-40B-025T | M8 | 10 | 82 | 313 | 48 | 290 | 8 | 6 |

| GMB-4-40C-037T | M8 | 10 | 82 | 313 | 48 | 290 | 8 | 6 |

| GMB-4-45A-037T | M8 | 12 | 82 | 363 | 48 | 332 | 8 | 6 |

| GMB-4-45B-055T | M8 | 12 | 82 | 363 | 48 | 332 | 8 | 6 |

| GMB-4-45C-075T | M8 | 12 | 82 | 363 | 48 | 332 | 8 | 6 |

| GMB-4-50A-075T | M8 | 12 | 82 | 413 | 48 | 372 | 12 | 6 |

| GMB-4-50B-110T | M8 | 12 | 82 | 413 | 48 | 372 | 12 | 6 |

| GMB-4-50C-150T | M8 | 12 | 82 | 413 | 48 | 372 | 12 | 6 |

| GMB-4-56A-110T | M8 | 12 | 82 | 473 | 48 | 422 | 12 | 6 |

| GMB-4-56B-150T | M8 | 12 | 82 | 473 | 48 | 422 | 12 | 6 |

| GMB-4-56C-220T | M8 | 12 | 82 | 473 | 48 | 422 | 12 | 6 |

| GMB-4-63A-220T | M10 | 12 | 533 | 48 | 482 | 504 | 12 | 6 |

| GMB-4-63B-300T | M10 | 12 | 533 | 48 | 482 | 504 | 12 | 6 |

| GMB-4-63C-400T | M10 | 12 | 533 | 48 | 482 | 504 | 12 | 6 |

| GMB-4-71A-400T | M10 | 14 | 82 | 613 | 82 | 513 | 12 | 6 |

| GMB-4-71B-550T | M10 | 14 | 82 | 613 | 82 | 513 | 12 | 6 |

| GMB-4-71C-750T | M10 | 14 | 82 | 613 | 82 | 513 | 12 | 6 |

| GMB-4-80A-750T | M10 | 14 | 698 | 82 | 593 | 332 | 16 | 6 |

| GMB-4-80B-1100T | M10 | 14 | 698 | 82 | 593 | 332 | 16 | 6 |

| GMB-4-80C-1500T | M10 | 14 | 698 | 82 | 593 | 332 | 16 | 6 |

| GMB-6-71A-110T | M10 | 14 | 82 | 613 | 82 | 513 | 12 | 6 |

| GMB-6-71B-150T | M10 | 14 | 82 | 613 | 82 | 513 | 12 | 6 |

| GMB-6-71C-220T | M10 | 14 | 82 | 613 | 82 | 513 | 12 | 6 |

| GMB-6-80A-220T | M10 | 14 | 698 | 82 | 593 | 332 | 16 | 6 |

| GMB-6-80B-300T | M10 | 14 | 698 | 82 | 593 | 332 | 16 | 6 |

| GMB-6-80C-400T | M10 | 14 | 698 | 82 | 593 | 332 | 16 | 6 |

Additional equipment