Fan Selection Software

Operating point

Select fan type

MPT

Centrifugal fan

Medium-pressure centrifugal fans with direct drive. MPT fans have many applications in industry, including air supply to gas burner systems, filtration systems, exhaust gases for slightly contaminated air.

Can be painted in a color

other than standard

other than standard

APPLICATION

The fan is designed for air extraction systems with low dust level and pneumatic transport.

Typical applications:

- supplying air to gas systems

- extraction of slightly polluted air

- air filtration systems

CONSTRUCTION

- medium-pressure centrifugal fan with direct drive

- impeller with straight blades, riveted from steel sheet, dynamically balanced according to ISO 1940-1

- housing is welded from steel sheet

- inlet protective mesh

- fan painted blue RAL 5010 (corrosivity category C3)

- maximum temperature of the transported medium 80°C

- figure LG270

MOTOR

- asynchronous, three-phase, 230/400V, 50 Hz or 400/690V, 50Hz depending on motor power

- degree of protection IP55

- insulation class F

- for frequency control

- motor ambient temperature from -20°C to +40°C

SPECIAL EXECUTIONS

- optional configuration LG/RD

- color other than standard

- painting in a higher corrosivity category

- impeller, housing, and base made of galvanized steel sheet

- impeller, housing, and base made of stainless steel 1.4301

- impeller, housing, and base made of acid-proof steel 1.4404

- motor with voltage and frequency of power different than standard

- motor with other than standard degree of protection

- motor equipped with sensors or additional cooling

- sealing between the housing and the motor

- motor ambient temperature range below -20°C and above +40°C

- maximum temperature of the transported medium above 80°C

Work characteristics

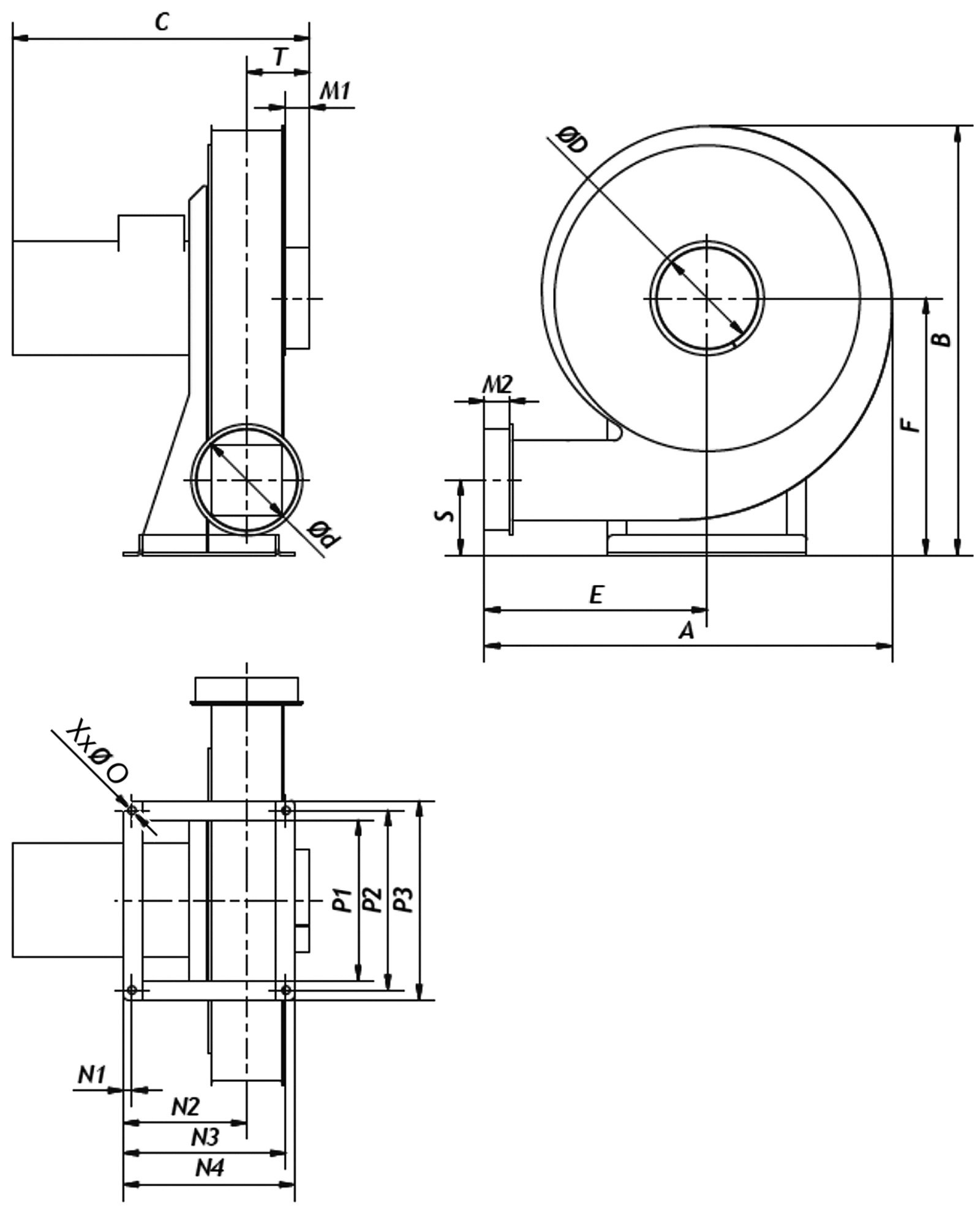

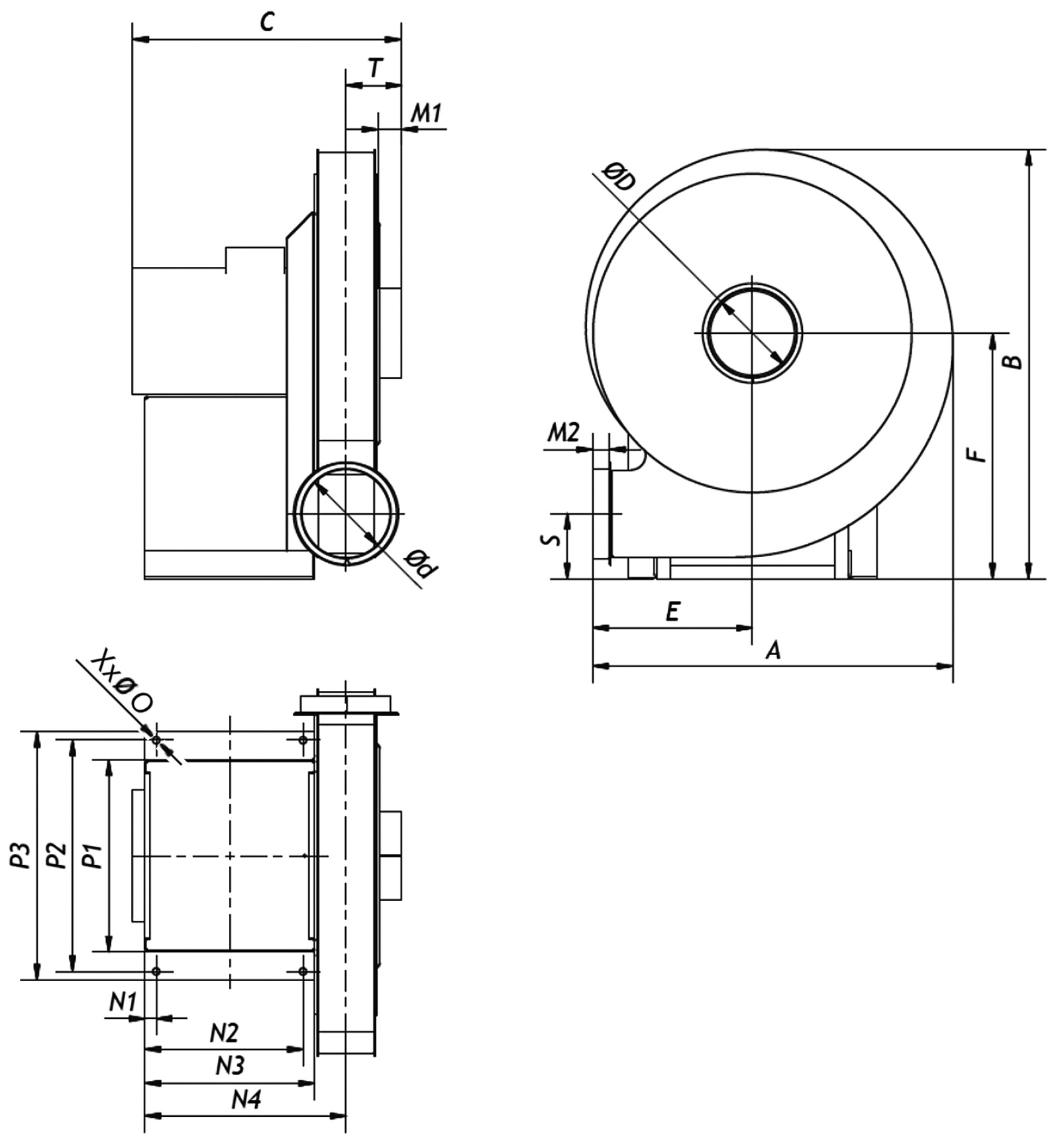

Dimensions

| Type | A | B | C | E | F | O | S | T | X | M1 |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| MPT-2-440/40-110T | 625 | 668 | 377 | 337 | 400 | 12 | 116 | 94 | 4 | 75 |

| MPT-2-440/40-150T | 625 | 668 | 377 | 337 | 400 | 12 | 116 | 94 | 4 | 75 |

| MPT-2-440/40-220T | 636 | 668 | 464 | 348 | 400 | 12 | 117 | 98 | 4 | 40 |

| MPT-2-440/40-300T | 636 | 668 | 464 | 348 | 400 | 12 | 117 | 98 | 4 | 40 |

| MPT-2-520/40-400T | 638 | 760 | 537 | 283 | 435 | 12 | 117 | 98 | 4 | 40 |

| Type | M2 | N1 | N2 | N3 | N4 | P1 | P2 | P3 | ØD | Ød |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| MPT-2-440/40-110T | 30 | 14 | 178 | 254 | 267 | 250 | 280 | 310 | 123 | 123 |

| MPT-2-440/40-150T | 30 | 14 | 178 | 254 | 267 | 250 | 280 | 310 | 123 | 123 |

| MPT-2-440/40-220T | 40 | 14 | 193 | 254 | 267 | 250 | 280 | 310 | 159 | 159 |

| MPT-2-440/40-300T | 40 | 14 | 193 | 254 | 267 | 250 | 280 | 310 | 159 | 159 |

| MPT-2-520/40-400T | 28 | 20 | 356 | 280 | 300 | 250 | 280 | 310 | 158 | 159 |

| Type | A | B | C | E | F | O | S | T | X | M1 |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| MPT-2-520/40-550T | 638 | 760 | 477 | 283 | 435 | 12 | 116 | 98 | 4 | 40 |

| MPT-2-520/40-750T | 638 | 760 | 477 | 283 | 435 | 12 | 116 | 98 | 4 | 40 |

| MPT-2-600/40-750T | 767 | 880 | 653 | 359 | 504 | 14 | 154 | 148 | 4 | 60 |

| MPT-2-600/40-1100T | 767 | 880 | 653 | 359 | 504 | 14 | 154 | 148 | 4 | 60 |

| Type | M2 | N1 | N2 | N3 | N4 | P1 | P2 | P3 | ØD | Ød |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| MPT-2-520/40-550T | 30 | 20 | 280 | 300 | 356 | 340 | 410 | 440 | 159 | 159 |

| MPT-2-520/40-750T | 30 | 20 | 280 | 300 | 356 | 340 | 410 | 440 | 159 | 159 |

| MPT-2-600/40-750T | 60 | 55 | 265 | 320 | 405 | 389 | 447 | 489 | 250 | 199 |

| MPT-2-600/40-1100T | 60 | 55 | 265 | 320 | 405 | 389 | 447 | 489 | 250 | 199 |

Additional equipment