Fan Selection Software

Operating point

Select fan type

DSC/PSC

Side channel blower

A two-stage side-channel fan with direct drive for oil-free transport of non-aggressive and non-explosive gases or for the production of over and underpressure.

Can be painted in a color

other than standard

other than standard

APPLICATION

Side-channel blowers are used in pneumatic transport.

Typical applications:

- pneumatic transport,

- graphic machines, pneumatic lifts, multi-stage filtration devices with a very high degree of dust separation,

- industrial vacuum cleaners, pools, aeration in biological sewage treatment plants, electroplating plants, etc.,

CONSTRUCTION

- two-stage side-channel blower with direct drive, designed for oil-free transport of non-aggressive and non-explosive gases.

- the impeller is made of aluminum alloy, dynamically balanced according to ISO 1940-1,

- the housing is cast in aluminum alloy,

- blower adapted to work in horizontal position,

- standard color of the blower is gray RAL 7042,

MOTOR

- asynchronous, three-phase 400V 50Hz or 400V / 690V 50Hz (depending on the motor power),

- degree of protection IP55,

- insulation class F,

- thermal protection (TP or TP and PTC)

Technical assistance

Work characteristics

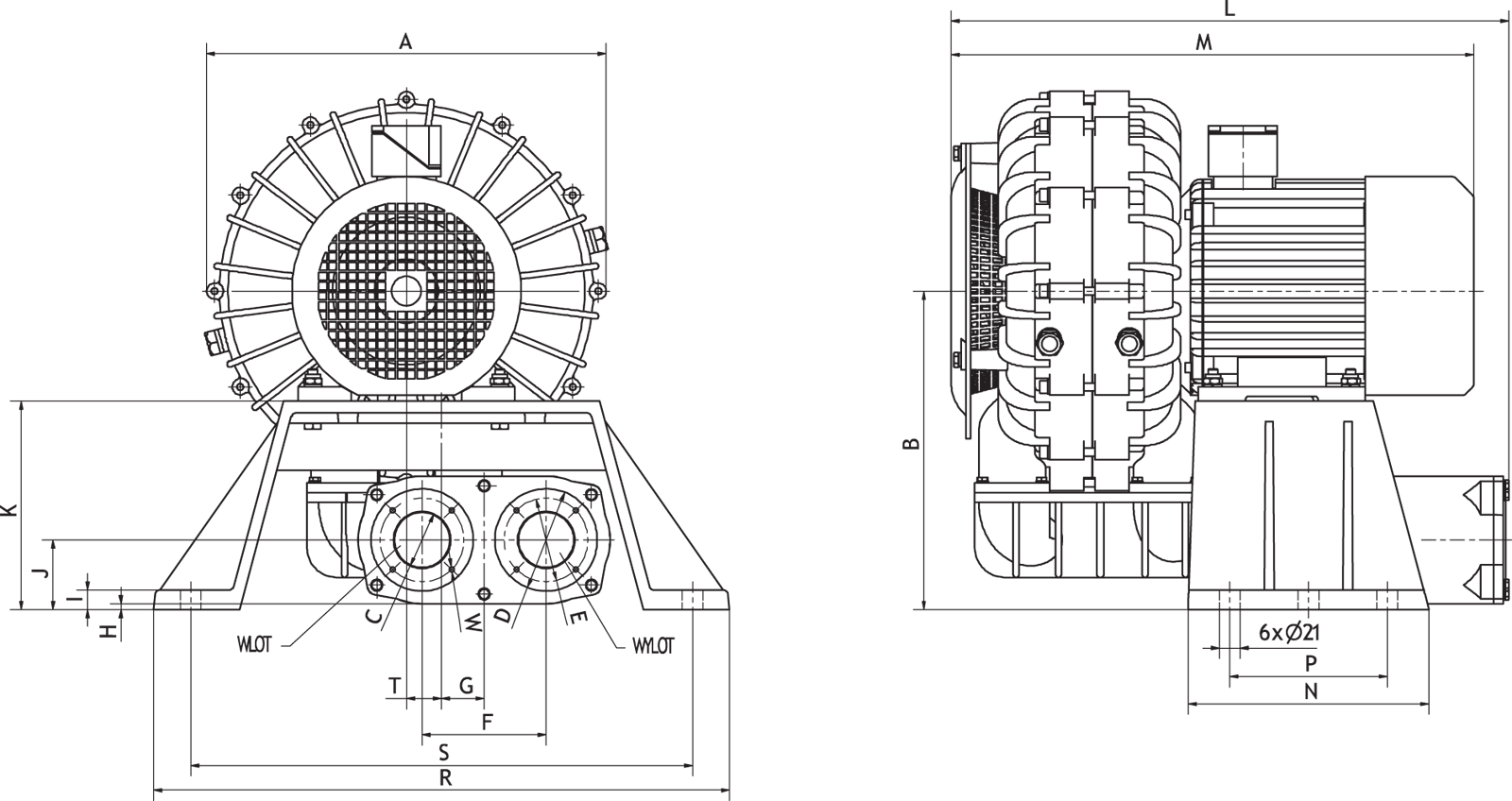

Dimensions

| Type | B | F | G | H | I | J | K | L | M | N |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| PSC30C550T (vacuum) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| PSC30C550T (pressure) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| PSC30C750T (vacuum) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| PSC30C750T (pressure) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| PSC40A750T (vacuum) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| PSC40A750T (pressure) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| PSC40A1100T (vacuum) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| PSC40A1100T (pressure) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| PSC40A1500T (vacuum) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| PSC40A1500T (pressure) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| DSC30C550T (vacuum) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| DSC30C550T (pressure) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| DSC30C750T (vacuum) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| DSC30C750T (pressure) | 324 | 126 | 43.5 | 6.2 | 20 | 71 | 212 | 567 | 531 | 245 |

| DSC40A750T (vacuum) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| DSC40A750T (pressure) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| DSC40A1100T (vacuum) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| DSC40A1100T (pressure) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| DSC40A1500T (vacuum) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| DSC40A1500T (pressure) | 407 | 145 | 32.5 | 1.5 | 20 | 76.5 | 275 | 653 | 584 | 340 |

| Type | P | R | S | T | W | ØA | ØC | ØD | ØE |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |

| PSC30C550T (vacuum) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| PSC30C550T (pressure) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| PSC30C750T (vacuum) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| PSC30C750T (pressure) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| PSC40A750T (vacuum) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| PSC40A750T (pressure) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| PSC40A1100T (vacuum) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| PSC40A1100T (pressure) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| PSC40A1500T (vacuum) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| PSC40A1500T (pressure) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| DSC30C550T (vacuum) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| DSC30C550T (pressure) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| DSC30C750T (vacuum) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| DSC30C750T (pressure) | 160 | 585 | 510 | 79 | 6 | 406 | 58 | 104 | 85 |

| DSC40A750T (vacuum) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| DSC40A750T (pressure) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| DSC40A1100T (vacuum) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| DSC40A1100T (pressure) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| DSC40A1500T (vacuum) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |

| DSC40A1500T (pressure) | 260 | 600 | 520 | 74.5 | 8 | 502 | 75 | 130 | 110 |